Smart Factory and Industry 4.0 Integration Services

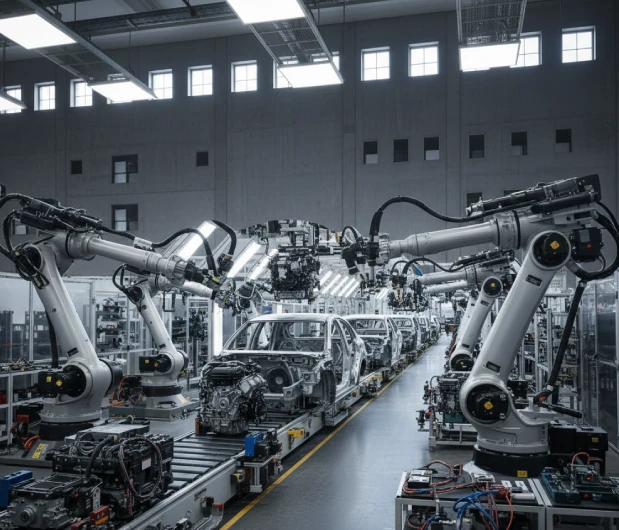

IMARC Engineering delivers comprehensive smart factory and Industry 4.0 integration services that transform traditional manufacturing operations into intelligent, connected production environments. With extensive expertise across pharmaceuticals, automotive, chemicals, food processing, and advanced manufacturing sectors, we develop strategic roadmaps bridging the gap between current capabilities and digital excellence.

Our multidisciplinary team of automation engineers, data scientists, and manufacturing specialists designs Industry 4.0 strategies integrating IoT sensors, artificial intelligence, predictive analytics, and systems, while assessing infrastructure, prioritizing investments, and delivering phased implementation plans that improve efficiency, quality, and visibility.

From initial digital maturity assessments to complete smart factory transformations, we partner with manufacturers navigating technological complexity, minimizing implementation risks, and maximizing return on digital investments. Our integration plans provide detailed blueprints, including technology architecture, vendor selection criteria, cybersecurity frameworks, workforce development strategies, and performance metrics, aligning digital capabilities with business objectives.

Our Strategic Approach to Smart Factory and Industry 4.0 Integration Services

Our structured methodology combines digital maturity assessment, technology evaluation, and strategic roadmap development to deliver actionable transformation plans. This approach guarantees a thorough evaluation of operational requirements, technological capabilities, and implementation priorities for successful digital manufacturing adoption.

Digital Maturity Assessment & Requirements Analysis

Evaluating current manufacturing systems, automation levels, and data infrastructure while identifying gaps, opportunities, and strategic objectives for digital transformation.

Technology Selection & Architecture Design

Selecting optimal Industry 4.0 technologies including IoT platforms, analytics tools, and automation systems while designing integrated architecture meeting operational requirements.

Implementation Roadmap & Investment Planning

Creating phased implementation plans with prioritized initiatives, resource requirements, investment estimates, and timelines for progressive digital capability building.

Change Management & Performance Framework

Developing workforce training programs, organizational change strategies, cybersecurity protocols, and performance metrics to guarantee successful adoption and continuous improvement.

Why Choose IMARC for Smart Factory and Industry 4.0 Integration Planning

Our comprehensive Industry 4.0 integration approach combines technical expertise, strategic thinking, and practical implementation experience delivering transformation plans that balance innovation with operational reality, guaranteeing sustainable digital manufacturing success.

Technology-Agnostic Recommendations

Receive unbiased technology recommendations based on operational requirements rather than vendor relationships. Our independent assessments identify optimal solutions balancing capability, compatibility, and investment efficiency for sustainable outcomes.

Phased Implementation Reducing Risk

Minimize transformation risks through carefully structured implementation phases delivering progressive value. Our roadmaps prioritize quick wins alongside foundational capabilities, guaranteeing continuous operational stability throughout digital adoption.

Manufacturing-Specific Expertise

Benefit from deep understanding of manufacturing operations, production processes, and quality requirements. Our team translates Industry 4.0 concepts into practical applications addressing real operational challenges and improvement opportunities.

Measurable ROI & Business Case Development

Secure investment approvals with comprehensive business cases demonstrating expected returns. We quantify benefits including productivity gains, quality improvements, waste reduction, and operational cost savings supporting investment decisions.

Cybersecurity & Compliance Integration

Safeguard digital assets through integrated cybersecurity frameworks covering industrial control systems, data protection, and regulatory compliance. Our approach embeds security requirements from system architecture design through implementation, monitoring, and ongoing operational management.

Organizational Readiness & Change Management

Guarantee successful adoption through comprehensive change management addressing workforce skills, organizational culture, and operational processes. We develop training programs and transition strategies maximizing technology value realization.

Smart Factory and Industry 4.0 Integration Planning Across Manufacturing Sectors

IMARC Engineering develops industry-specific strategies addressing unique operational requirements, regulatory frameworks, and competitive dynamics. Our sector expertise guarantees digital transformation initiatives align with industry standards and deliver measurable competitive advantages.

Smart factory planning for pharmaceutical manufacturing incorporating GMP-compliant automation, electronic batch records, serialization integration, environmental monitoring systems, and data integrity frameworks. We address regulatory requirements while enhancing operational efficiency and compliance visibility.

Smart food manufacturing integration addressing automated processing lines, real-time quality monitoring, food safety compliance systems, cold chain management, batch traceability, and packaging automation. Our solutions incorporate HACCP-compliant monitoring, allergen control systems, shelf-life optimization, waste reduction analytics, and supply chain visibility guaranteeing food safety, operational efficiency, and regulatory compliance.

Industry 4.0 integration for chemical manufacturing addressing process control automation, safety system integration, real-time quality monitoring, batch optimization, and environmental compliance tracking. We incorporate advanced process analytics, predictive maintenance for critical equipment, inventory optimization, and supply chain coordination guaranteeing operational excellence while maintaining rigorous safety and environmental standards.

Smart manufacturing solutions for electronics production, semiconductor fabrication, and technology hardware manufacturing including automated material handling, cleanroom monitoring, precision quality inspection systems, and production traceability. Our integration plans optimize yield rates, reduce defects, enhance production flexibility, and enable rapid response to technology product lifecycle demands.

Digital transformation strategies for energy generation, transmission, and distribution facilities including smart grid integration, renewable energy management systems, predictive equipment maintenance, remote monitoring capabilities, and energy optimization analytics. Our solutions enhance operational reliability, optimize asset performance, improve safety protocols, and support transition toward sustainable energy operations.

Digital agriculture and agro-processing integration including precision agriculture systems, controlled environment agriculture automation, post-harvest processing optimization, cold chain monitoring, and agricultural supply chain visibility. We incorporate IoT sensors, climate control systems, irrigation automation, and quality tracking enhancing productivity, reducing waste, and guaranteeing food safety throughout agricultural operations.

Advanced manufacturing integration for automotive production including collaborative robotics, automated guided vehicles, digital quality inspection, production scheduling optimization, and supply chain synchronization. Our strategies address electric vehicle manufacturing requirements, Industry 4.0 compliance for OEM suppliers, predictive maintenance reducing assembly line downtime, and flexible manufacturing systems supporting product variety.

Advanced infrastructure solutions designed for construction materials manufacturing and building products facilities, supporting infrastructure operations through automated production, continuous quality monitoring, inventory optimization, coordinated logistics, and environmental compliance management. We develop digital strategies enhancing operational efficiency, material traceability, and project delivery capabilities across infrastructure manufacturing operations.

Comprehensive Industry 4.0 integration for discrete and process manufacturing including industrial automation, real-time production monitoring, predictive maintenance systems, quality control analytics, and supply chain visibility. Our strategies optimize production efficiency, reduce downtime, enhance quality consistency, and improve resource utilization through intelligent manufacturing systems.

Trusted by Industry Leaders

We partner with global enterprises and ambitious businesses across sectors to deliver operational excellence, strategic insights, and sustainable growth through comprehensive integrated solutions.

Success in Their Words

Real feedback from clients across industries. Discover how our solutions delivered measurable impact and operational excellence.

Frequently Asked Questions

We have compiled answers to common questions investors and manufacturing leaders ask about smart factory and integration plan. These insights address investment requirements, expected returns, implementation timelines, and strategic considerations for digital transformation.

Ready to Transform Your Manufacturing Operations?

Contact IMARC Engineering today to discuss your smart factory transformation objectives and discover how our Industry 4.0 integration planning services can enhance competitiveness, optimize operations, and position your enterprise for sustainable digital excellence.