Equipment Calibration and Vendor Coordination

IMARC Engineering delivers comprehensive equipment calibration and vendor coordination services that ensure measurement accuracy, regulatory compliance, and operational reliability across manufacturing facilities. With extensive expertise spanning pharmaceutical, food processing, chemical, and industrial manufacturing sectors, we provide systematic programs that maintain instrument precision while streamlining technical service relationships.

Our specialized team of metrology experts, quality engineers, and vendor management professionals conducts rigorous calibration oversight and supplier coordination. We establish documented programs covering measurement devices, analytical instruments, production machinery, and process control systems to guarantee accuracy standards throughout operations.

From calibration scheduling and documentation management to vendor selection and service oversight, we partner with manufacturers to build robust quality systems. Our solutions deliver traceable accuracy verification, regulatory documentation, streamlined vendor relationships, and cost-effective service management that supports both compliance objectives and operational excellence across manufacturing environments.

Our Structured Equipment Calibration and Vendor Coordination Methodology

Our comprehensive approach integrates meticulous calibration planning, rigorous accuracy verification, and strategic vendor relationship management. This proven methodology ensures measurement reliability, regulatory documentation, and efficient technical service coordination across manufacturing operations.

Instrument Assessment and Calibration Program Development

Inventorying measurement instruments, analyzing accuracy requirements, establishing calibration frequencies, and developing documented programs that align with regulatory standards and operational needs.

Vendor Selection and Service Agreement Establishment

Evaluating qualified calibration providers, negotiating service contracts, defining performance expectations, and establishing communication protocols for technical support and emergency response requirements.

Calibration Execution and Documentation Management

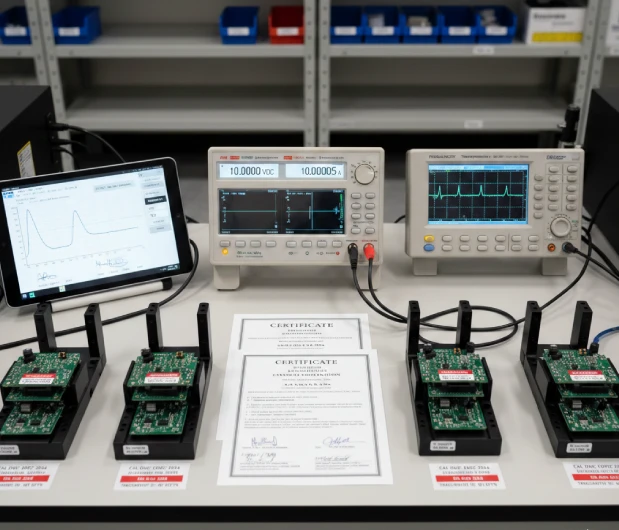

Coordinating scheduled calibrations, overseeing vendor performance, maintaining certification records, managing traceability documentation, and ensuring compliance with quality system requirements throughout execution.

Performance Monitoring and Continuous Improvement

Tracking service quality metrics, analyzing instrument performance trends, optimizing scheduling efficiency, and implementing corrective actions that enhance accuracy assurance and vendor relationship effectiveness.

Why Choose IMARC for Equipment Calibration and Vendor Coordination

Our systematic approach delivers measurement reliability, regulatory compliance assurance, and operational efficiency across technical service management. This comprehensive methodology addresses accuracy verification, documentation integrity, vendor performance, and cost optimization throughout calibration operations.

Regulatory Compliance and Audit Readiness Assurance

Maintain complete compliance with GMP, ISO, FDA, and industry-specific standards through documented programs, traceable certificates, and systematic record-keeping that withstands regulatory inspections and audit scrutiny.

Measurement Accuracy and Product Quality Protection

Ensure manufacturing precision through verified instrument accuracy, preventing quality deviations, product recalls, and customer complaints. Systematic calibration programs protect brand reputation by maintaining measurement reliability throughout production processes.

Streamlined Vendor Management and Service Efficiency

Simplify technical service coordination through centralized vendor relationships, standardized procedures, and clear communication protocols. Reduce administrative burden while ensuring consistent service quality and responsive technical support across operations.

Cost Optimization Through Strategic Service Planning

Reduce calibration expenses through optimized scheduling, consolidated vendor relationships, competitive service agreements, and preventive maintenance that extends instrument lifespan. Strategic planning eliminates redundant services while maintaining accuracy standards.

Operational Continuity and Downtime Minimization

Maintain production schedules through proactive calibration planning, scheduled maintenance coordination, backup instrument strategies, and rapid vendor response for unexpected failures. Minimize disruptions while ensuring measurement integrity across facilities.

Comprehensive Documentation and Traceability Systems

Establish robust record management covering certificates, procedures, schedules, and performance history. Digital documentation systems provide instant access for audits, investigations, and decision-making while ensuring complete traceability chains.

Specialized Equipment Calibration and Vendor Coordination Across Manufacturing Sectors

IMARC Engineering delivers industry-specific calibration management backed by deep sector knowledge and technical expertise. Our understanding of regulatory requirements, measurement standards, and operational demands ensures relevant solutions for manufacturing environments.

Expert calibration management for pharmaceutical manufacturing including analytical balances, HPLC systems, spectrophotometers, particle counters, environmental monitoring equipment, autoclave validation instruments, and stability chambers. We ensure GMP compliance through documented programs, traceable standards, qualification protocols, and vendor coordination that meets FDA, EMA, and international regulatory requirements for pharmaceutical production.

Comprehensive calibration oversight for food processing operations including thermometers, pH meters, metal detectors, checkweighers, viscosity meters, refractometers, water activity analyzers, and quality testing instruments. We manage vendor coordination ensuring HACCP compliance, food safety standards, and regulatory requirements throughout production, packaging, and storage operations.

Detailed calibration oversight for chemical process instrumentation including pH meters, conductivity analyzers, flow meters, pressure transmitters, temperature sensors, gas detectors, and analytical laboratory equipment. We coordinate vendor services addressing hazardous area requirements, process safety standards, environmental compliance, and quality specifications unique to chemical manufacturing operations.

Advanced calibration programs for electronics manufacturing and technology production including coordinate measuring machines, optical inspection systems, environmental test chambers, soldering temperature profilers, electrical test equipment, and precision assembly instrumentation. We manage vendor coordination supporting tight tolerance requirements, rapid production cycles, and quality standards throughout technology manufacturing environments.

Specialized calibration coordination for power generation and distribution equipment including electrical meters, protective relays, transformer test equipment, vibration analyzers, thermal imaging devices, and emissions monitoring systems. We manage vendor relationships for critical instrumentation ensuring measurement accuracy for safety systems, efficiency monitoring, regulatory reporting, and preventive maintenance across energy infrastructure.

Comprehensive calibration management for agricultural processing and production facilities including moisture analyzers, nutrient testing equipment, grain quality instruments, climate control systems, irrigation controllers, and pesticide application devices. We coordinate vendor services ensuring accuracy for crop quality assessment, processing specifications, storage monitoring, and regulatory compliance across agricultural operations.

Expert calibration coordination for automotive manufacturing including dimensional inspection tools, torque wrenches, alignment equipment, paint thickness gauges, emissions analyzers, dynamometer systems, and quality control instrumentation. We manage vendor relationships supporting stringent tolerance requirements, traceability demands, and quality standards throughout automotive component production and vehicle assembly operations.

Specialized calibration programs for construction and infrastructure projects including concrete testing equipment, asphalt measurement devices, soil analysis instruments, structural monitoring systems, surveying equipment, and materials testing apparatus. We coordinate vendor services across multiple project sites ensuring measurement accuracy for quality assurance, specification compliance, and safety verification throughout infrastructure development.

Comprehensive calibration programs for industrial manufacturing instruments including dimensional measurement tools, pressure gauges, temperature devices, weighing scales, torque equipment, and process control instrumentation. We coordinate vendor services across production facilities, ensuring accuracy standards for quality control, process validation, and product specifications throughout manufacturing operations.

Trusted by Industry Leaders

We partner with global enterprises and ambitious businesses across sectors to deliver operational excellence, strategic insights, and sustainable growth through comprehensive integrated solutions.

Success in Their Words

Real feedback from clients across industries. Discover how our solutions delivered measurable impact and operational excellence.

Frequently Asked Questions

We've compiled answers to the most common questions investors, business owners, and quality managers ask about equipment calibration and vendor coordination. These insights address critical concerns around compliance requirements, operational implementation, and service management.

Ready to Strengthen Your Calibration Program?

Contact our calibration management team today to discuss your measurement accuracy requirements and discover how IMARC Engineering can deliver systematic programs ensuring precision, compliance, and operational excellence throughout your facilities.