Production Ramp-up Monitoring

IMARC Engineering provides comprehensive end-to-end production ramp-up monitoring solutions that help manufacturers accelerate process stabilization, reduce inefficiencies, and achieve steady-state performance faster. Our tailored approach uses data analytics, digital tools, and engineering insights to ensure seamless transitions from pilot to full-scale operations.

Our team of experienced engineers evaluates critical production parameters, such as equipment reliability, material flow, and operator readiness. They identify deviations early, allowing timely interventions that mitigate downtime and quality inconsistencies across your operations. This proactive approach enhances throughput, reduces process losses, and improves synchronization between production teams and supporting departments.

Through detailed performance tracking, variance analysis, and predictive modeling, we help clients establish structured ramp-up frameworks. These ensure predictable output rates, optimized resource utilization, and robust quality control while minimizing the risks associated with scaling operations. Our monitoring framework guarantees reliability and transparency across every production phase.

Our Production Ramp-up Monitoring Methodology

Our structured production ramp-up monitoring process ensures precise control, continuous evaluation, and systematic improvement throughout production scale-up. Each stage is data-driven, enabling consistent output, minimized downtime, and enhanced operational readiness.

Pre-Ramp-Up Assessment and Planning

We define objectives, collect baseline data, and identify process sensitivities to prepare operations, ensuring all systems, materials, and personnel are aligned for a stable startup phase.

Performance Tracking and Data Analysis

Real-time metrics such as cycle time, yield, and equipment utilization are monitored to detect deviations, inefficiencies, or control issues during early production activities.

Corrective Action and Optimization

Observed discrepancies are analyzed, root causes identified, and process adjustments implemented through coordinated efforts between engineering, production, and maintenance teams.

Stabilization and Performance Validation

We confirm sustained achievement of performance targets, verify efficiency levels, and document improvements to validate operational readiness for long-term continuous production.

Why Choose IMARC for Production Ramp-up Monitoring

Our ramp-up monitoring methodology integrates real-time analytics, process engineering, and performance management to deliver precise production acceleration. This systematic approach ensures stability, efficiency, and measurable gains across every stage of scaling operations.

Accelerated Time-to-Stability

We accelerate production maturity by identifying and correcting process inefficiencies early. Our structured monitoring minimizes ramp-up delays, stabilizes equipment operations, and ensures faster achievement of output targets while maintaining consistent quality and throughput across all manufacturing shifts.

Enhanced Process Reliability

Our approach focuses on eliminating variability in production parameters through detailed data analysis and process validation. This ensures sustained process reliability, reduces downtime events, and promotes predictable operational performance essential for long-term manufacturing stability and investor confidence.

Quality Assurance Integration

We embed robust quality management throughout the ramp-up process, continuously monitoring defect trends, yield deviations, and process capability indices. This ensures adherence to global quality standards while enabling consistent, compliant, and defect-free production across expanding manufacturing operations.

Data Transparency and Insight

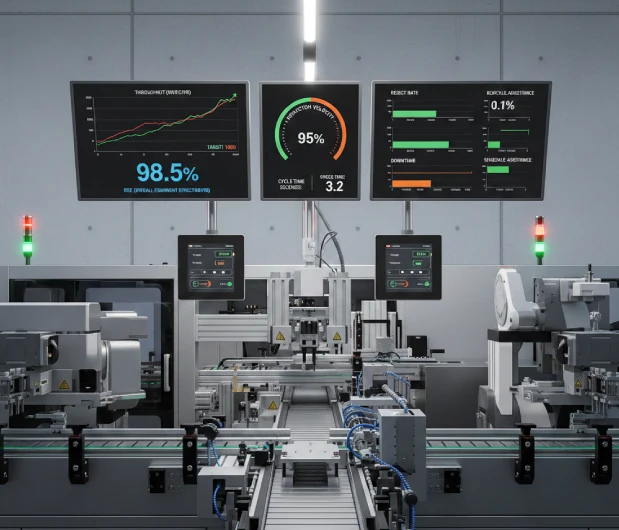

IMARC Engineering provides clients with advanced performance dashboards that track real-time key performance indicators. These customized analytics enable transparent decision-making, improve process visibility, and empower stakeholders with accurate, actionable intelligence throughout every ramp-up phase.

Risk Mitigation and Cost Control

Through continuous data monitoring and issue escalation protocols, we identify and mitigate production risks before they escalate into costly disruptions. Our structured intervention strategies minimize downtime, prevent material wastage, and optimize operating costs during critical scale-up periods.

Sustained Operational Excellence

Our engagement continues beyond stabilization, focusing on continuous process refinement and capability enhancement. We develop predictive maintenance models, efficiency tracking systems, and long-term improvement plans to sustain operational excellence and ensure measurable returns on manufacturing investments.

Specialized Production Ramp-up Monitoring Across Industries

IMARC Engineering delivers various tailored production ramp-up monitoring solutions that address sector-specific challenges and technical requirements. Our specialized expertise ensures operational readiness, process efficiency, and accelerated time-to-market across diverse industries.

We oversee pharmaceutical and medical manufacturing scale-ups by validating process reproducibility, batch uniformity, and GMP compliance. Our monitoring ensures sterile operations, calibrated equipment, and seamless coordination between R&D and production units, enabling regulatory-ready, quality-assured product launches and sustained compliance with global health authority standards.

We manage ramp-up for food and beverage plants by optimizing process flow, sanitation cycles, and packaging efficiency. Our teams monitor temperature control, quality checkpoints, and production hygiene to ensure consistent throughput, minimized waste, and continuous compliance with food safety regulations across high-volume processing operations.

Our ramp-up monitoring in chemical and petrochemical facilities ensures safe and efficient transitions to full-scale output. We evaluate process reactions, temperature gradients, emissions, and material flows, enabling performance stability, regulatory adherence, and reliable operation of hazardous systems under continuous manufacturing conditions.

We monitor turbine and generation unit ramp-ups across renewable and conventional energy facilities. Our oversight validates efficiency benchmarks, fuel system synchronization, and grid integration readiness, ensuring operational continuity, minimized commissioning losses, and optimized power generation performance from initial synchronization to sustained output.

Our team supports ramp-up in semiconductor, electronics, and high-precision component facilities by tracking yield consistency, defect density, and cleanroom stability. Through automated data analytics, we ensure process reproducibility, equipment uptime, and environment control, delivering precise, reliable, and cost-efficient performance for advanced manufacturing operations.

We facilitate stable scale-up of agro-processing facilities by monitoring throughput balance, equipment coordination, and storage efficiency. Our systems assess seasonal supply variations, resource utilization, and operational synchronization, ensuring continuous production flow, minimized spoilage, and improved output stability across agricultural manufacturing operations.

We guide automotive manufacturers during production acceleration by monitoring assembly accuracy, robotic calibration, and takt time adherence. Our team optimizes process synchronization, ensures defect-free assembly, and reduces rework cycles, supporting faster stabilization and high-quality output across complex automotive production environments.

Our ramp-up monitoring for cement, steel, and materials plants focuses on stabilizing mechanical systems, maintaining throughput uniformity, and improving energy efficiency. We validate production parameters, align process settings, and enhance operational readiness to ensure sustainable, cost-efficient, and high-capacity manufacturing performance.

We provide monitoring solutions for general manufacturing industries to ensure rapid stabilization of production processes. Our team assesses machine performance, material flow, and labor utilization, delivering improved consistency, capacity optimization, and operational resilience for scalable, diversified industrial manufacturing growth.

Trusted by Industry Leaders

We partner with global enterprises and ambitious businesses across sectors to deliver operational excellence, strategic insights, and sustainable growth through comprehensive integrated solutions.

Success in Their Words

Real feedback from clients across industries. Discover how our solutions delivered measurable impact and operational excellence.

Frequently Asked Questions

We’ve compiled detailed insights addressing key investor concerns related to production ramp-up monitoring. These responses explain how our solutions enhance efficiency, reduce operational risks, and ensure smooth transitions from commissioning to full-scale production.

Ready to Accelerate Your Manufacturing Ramp-up?

Contact IMARC Engineering’s production optimization specialists today to discuss how our ramp-up monitoring solutions can help you achieve faster stabilization, minimize risks, and maximize manufacturing efficiency. Let’s ensure your production success from the very first run.